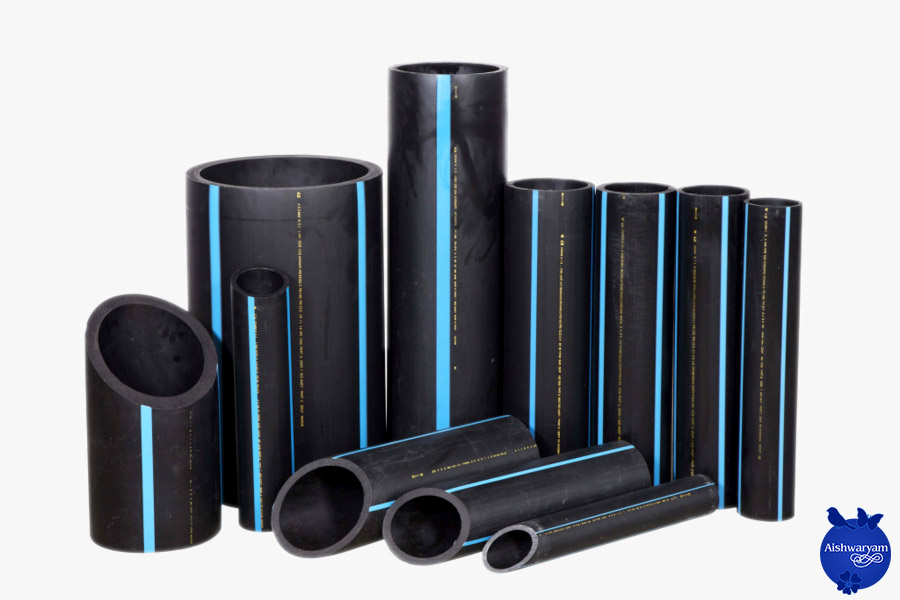

HDPE PIPES

HDPE Pipes made from Polyethylene (PE) is a cost effective answer for a number of piping problems in Metropolitan, Municipal, Industrial, Underwater, Mining, Landfill Gas extraction, Cable duct and agricultural applications. It has been tested and proven effective for underground, above ground, surface, under water as well as floating pipe applications, Available in 20mm to 1000mm Range.

Polyethylene pipes both High Density (HDPE) and Medium Density (MDPE) can carry potable water, wastewater, slurries, chemicals, hazardous wastes, cables and compressed gases as well as oils. Polyethylene pipes have a long and successful service experience to the gas oil, mining and water utility industries. PE pipes have the lowest repair frequency per Kilometer of pipe per year compared with all other pipe materials used for urban water and gas distribution.

AishwaryamHDPE pipes are strong, extremely tough and long lasting. AishwaryamHDPE pipes will meet all your requirements of long service, trouble-free installation, flexibility, resistance to corrosion and chemicals.

RANGE

- Our current range of HDPE pipes are available in sizes 20 to 1000mm, OD pressure rating from PN-2.5 to PN-16.5

APPLICATIONS

- Chemical / Processing Industries

- Not affected by acid and alkali

- Smooth continuous flow of water due to smooth inner surface

- For carrying Natural Gas, Coal Gas, Bio – Gas, etc. for domestic and industrial purposes

- For carrying Soil, waste from the SWR Drainage System to appropriate drains or sewers through an underground network of pipes

FEATURES

- Corrosion Resistant

- HDPE pipes do not rust rot or corrode. HDPE is one of the most chemically inert of all plastics and therefore is extremely chemical and corrosion resistant.

- HDPE has low notch sensitivity and high tear strength At the same time, being flexible, HDPE performs well in both high cover and low cover applications. It’s unique ability to support and distribute live and dead load enables it to meet almost every installation conditions.

- Holding and installation cost is considerably reduced due to light weight feature while long lengths reduces jointing and fitting cost for e.g. Sizes up to 110mm pipe is available in coil form of 250-500 meters. Coil lengths can be increased in case of sizes from 20mm to 50mm OD

- HDPE is one of the most chemically inert of all plastics and with high resistance to abrasion. These two characteristics give HDPE pipe a significant long term advantage.

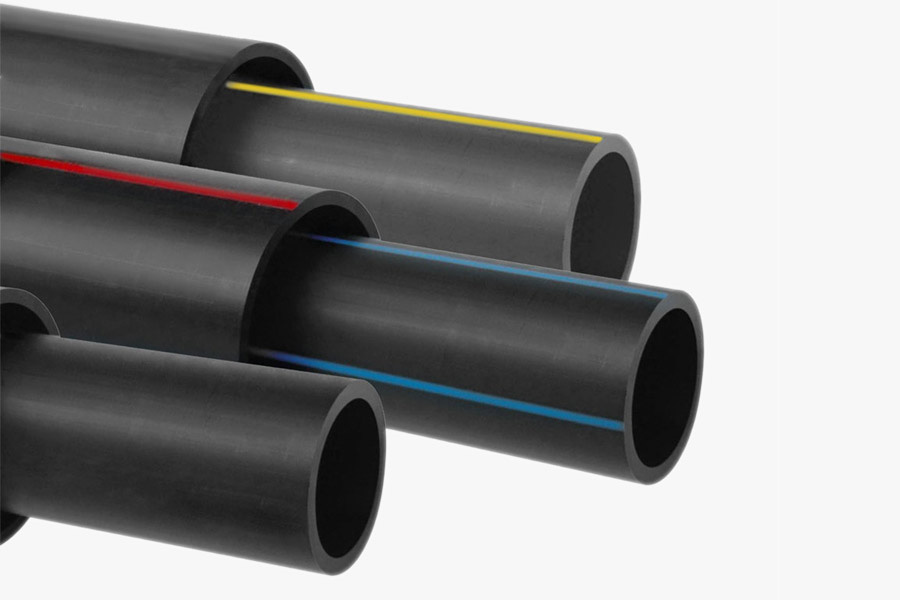

- Black HDPE contains approx. 2.5% ± 0.5% carbon black and can be safely stored and installed in non – covered areas.

- HDPE could be joined both mechanically by Flange Joint or Butt Welding method at site with HDPE Couplers/Sockets.

- HDPE pipes are available in a range of pressure ratings from PN 2.5-4-6-8 10-12.5 and 16 (PN stands for Kgf/cm2).